Technology Transfer for RFID Assessment in Cake supply chain (TETRACAKE)

Food chain traceability is a serious challenge not only in terms of consumer safety but also for all the stakeholders along the supply chain as well as national governments and the European Union.

TETRACAKE TP is aimed at transferring the University of Salento recognized skills on UHF RFID technology into the cake production chain so to significantly enhance traceability of both fresh and frozen pastries and make a return on investment for the SME partner, MARTINUCCI srl.

The TP was subdivided into three Work Packages. More specifically, in WP1 the business process analysis of MATINUCCI s.r.l. processes has been conducted and the criticalities from the electromagnetic point of view associated to the potential introduction of the RFID technology along the cake and frozen cake supply chain have been individuated. In particular the strategic sites/assets/procedures suitable for the transfer of the advanced RFID technology have been individuated and the specific issue of the RFID‐based traceability in the cold rooms has been identified as the most challenging one from the electromagnetic point of view, because of the rigid temperatures (‐27 °C) and the presence of ice, frozen pastries, and metallic assets.

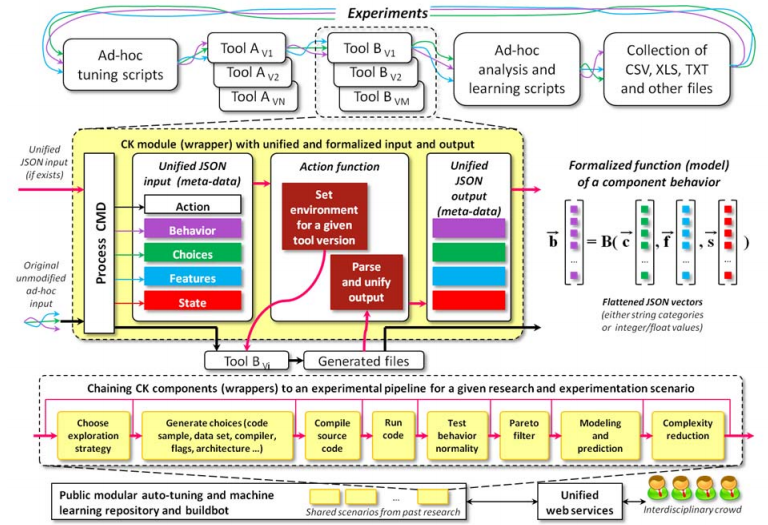

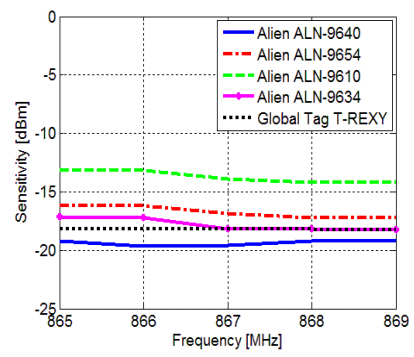

In WP2 the requirements in terms of RFID chips, RFID readers, reader‐antennas, and above all RFID tag antennas, have been individuated. Suitable hardware has been then selected and preliminarily tested at the University’s RFID laboratories through the system reported in Fig. 1. A complex electromagnetic analysis aimed at evaluating the performance of RFID tags has been conducted through a measurement system capable of assessing the sensitivity of each tag under test in the European dedicated RFID frequency band. One of the many results obtained in terms of RFID tag taxonomy is reported in Fig. 2.

Fig. 1: Measurement system for RFID tags performance evaluation

Fig. 2: Taxonomy of RFID tags in terms of sensitivity.

The most performing tags have been validated along with our patented solution at MARTINUCCI’s facilities in order to study the RFID system performance in potential different scenarios.

In particular, a selection of RFID tags has been applied to boxes containing frozen pastries and have been left exposed to a temperature as low as ‐27 °C for three months. The performance of the tags has been evaluated first and after the exposure, and tags suitable our purposes have been individuated.

In Fig. 3‐5 some pictures taken during the experimentation phase are shown.

Fig. 3: Cold room entry. The most critical step in the Martinucci’s supply chain is the storage in the cold rooms, because of the very low temperature (‐27 °C) that can impact on the performance of both RFID readers and tags.

Fig. 4: RFID tags applied on cake boxes and stored in the cold room along with a reder antenna. Some tags did not change their performance at all after a three‐month exposure.

Fig. 5: One oft he tagged boxes after the three‐mont exposure. One of the tags selected during the TP works properly even if covered by ice.

Finally, during WP3 the knowledge transfer has been finalized through the training of some company employees.

The success of the TP enforced the collaboration between University of Salento and MARTINUCCI s.r.l.. The Company partner is now acquiring hardware and under the guidance of University of Salento is step by step introducing RFID technology in their processes.