OPTIGLASS: Application of Artificial Intelligence-based techniques for optimizing the continuous Glass Cutting Problem

In automated float glass manufacturing, a continuous ribbon of glass is cut according to customer orders. This process involves many tasks that must be optimized to improve profitability. This industry is considered an energy intensive industry, so the main objective is to maximize the production of glass with the given energy consumption. Thus, the profitability of applying intelligent techniques to optimize problems associated to this process is twofold: the company remains more competitive and also it is more sustainable.

In this TTP, we are focusing on designing and transfer Artificial Intelligence‐based technology to solve interrelated scheduling problems involved in a glass manufacturing company. These problems can be summarized in:

- The customer order selection problem. This problem aims to select, from the batch of all customer orders, the more appropriate ones to be inserted into the system. The selected orders will be served and they will be the input of the glass cutting algorithm.

- The glass cutting problem. The main goal of this problem is to generate the sequence of sheets of the input customer orders to minimize the layout cullet.

To this end, a simulation tool has been developed to analyze the best customer order selection problem and solve the glass cutting problem.

Float glass manufacturing is a continuous process whereby a ribbon of molten glass is produced in a furnace and then cooled on a bath of molten tin to ensure flatness. The stream of glass is pulled along the top of the molten tin by haul‐off conveyors at the end of the float area which transport the glass into the annealing lehr. Then the sheet of glass is cut according to customer requirements, and it is offloaded for storage and distribution.

The information reported by the inspection scanners to detect flaws in the glass is stored and analyzed. Given this information, our tool carried out a preprocessing step to obtain feasible sections of glass that can satisfy the customer requirement according to quality constraints. Thus, the developed algorithm determines the best glass sheet that minimizes the cullet. This algorithm must search for all sheet possibilities to decide which sheet must be selected to be cut. Figure 1 shows the flow of the developed algorithm to minimize the cullet in the glass cutting problem. It is necessary that the algorithm finishes in a given time due to the continuous glass manufacturing process cannot stop. Thus, the algorithm includes a heuristic search technique to obtain anytime optimized solutions in order to be valid for all thickness ranges. It must be taken into account that as the glass thickness is smaller, the speed of the float glass is greater. The search algorithm analyzes all possible combinations of sheets and selects the best one in the given time.

Figure 1: The proposed scheduling algorithm to optimize the glass cutting problem

By using our simulation tool, the customer order selection problem can be solved with historic data. The experts of the company have a large log with data about the customer orders, and the glass waste obtained for each scheduling day. This has been very useful to develop the simulation tool to solve the customer order selection problem.

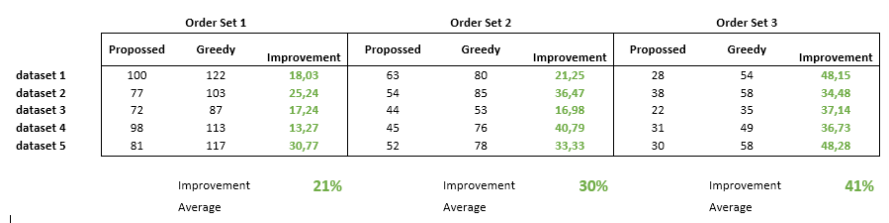

In the TTP, the proposed algorithm has been compared with the existing algorithm (Greedy) to analyze the behavior of both techniques and the achieved improvement. Figure 2 shows the behavior of both techniques with different order sets.

Figure 2: Evaluation and comparison of the proposed algorithm and the greedy existing one.

It can be observed that the improvement is significant in all the analyzed sets. However the improvement depends on the topology and distribution of flaws and also the customer order selection. As the customer orders are more heterogeneous, less cullet will be generated. Thus, our tool is able to select form a given set of customer orders which four will be managed together to minimize cullet.

The tool developed in this TTP has reduced the cullet of the company and increased the competitiveness of the company in the market. The company ensures that they save around 150,000€/year.